Call Anytime

+8613587606882- Home Page

- Company Profile

-

Our Products

- Capsule Filling Machine

- Blister Packing Machine

- Pharma Blister Packing Machine

- Automatic Blister Packing Machine

- Alu Alu Blister Packing Machine

- Chocolate Blister Packing Machine

- Liquid Blister Packing Machine

- Capsule Blister Packing Machine

- Pill Blister Packing Machine

- Small Blister Packing Machine

- Automatic Blister Packaging Machine

- Liquid Blister Packaging Machine

- Alu-alu Blister Packing Machine

- Alu PVC Blister Packing Machine

- Cartoning Machine

- Cosmetic Packing Machine

- Food Packaging Machine

- Horizontal Pouch Packaging Machine

- Mini Doypack Fill Seal Packaging Machine

- High Speed Packaging Machine

- Horizontal Automatic Packaging Machine

- Sachet Flat Bag Packaging Machine

- Industrial Doypack Horizontal Packaging Machine

- Industrial Automatic Packaging Machine

- Automatic Horizontal Packaging Machine

- Film Bunding Machine

- Heat Shrink Packaging Machine

- Overwrapping Packaging Machine

- Folding And Sealing Packaging Machine

- Overwrapping Machine

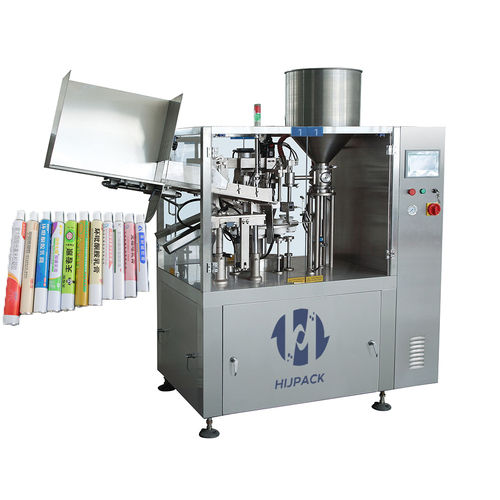

- Tube Filling And Sealing Machine

- Automatic plastic/laminated tube filling & sealing machine

- AUTO TUBE FILLING AND SEALING MACHINE

- Automatic Tube Filling And Sealing Machine

- NF-80AZ Automatic Plastic Laminated Tube Filling And Sealing Machine

- HIJ-TF60A Auto Tube Filling And Sealing Machine

- HIJ-TF120 Automatic Aluminum Tube Filling And Sealing Machine

- Prefilled Syringe Machine

- Counting Machine

- Vacuum Deduster

- Capsule polisher

- Contact Us

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese